Career

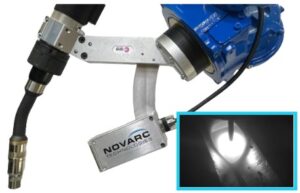

Novarc Technologies

(Vancouver, BC, Canada) November 2021 - Present

Deputy Chief Technology Officer & Vice President of Innovations (Smarting Welding Robots)

I originally joined Novarc as the VP of Innovation with a really exciting goal: to take our success in pipe welding and expand it into new types of robotic systems. Novarc was already a leader in the field, so my job was to build a scalable foundation that could handle all sorts of different industrial setups. As our team’s impact grew and we started reaching these milestones, I stepped into my current role as Deputy CTO.

One of my favorite projects was leading the development of NovAI. It’s our robotic vision and perception platform that helps machines ‘see’ and adapt to the welding task in real-time. By using advanced sensors and data, we enabled the robots to handle things like seam tracking and gap compensation automatically. This made it much easier for our customers in the manufacturing sector to automate complex tasks and see a real return on their investment.

Beyond the engineering, I focused on the business side of innovation. I helped our team move from building prototypes to creating reliable, market-ready products. I’ve also been heavily involved in our company’s growth strategy, working on everything from Series A and B fundraising to building strategic partnerships. It’s been about making sure our long-term vision is backed by the right talent and capital.

My time at Novarc has really reinforced one thing: great innovation happens when you mix strong technology with solid leadership. Scaling automated systems isn’t just a technical puzzle; it’s about building trust in the field and making sure the whole organization is aligned. It’s a challenge I love, and it’s what keeps me excited about the future of smart manufacturing.

Applus SKC

(Vancouver, BC, Canada) February 2015 - November 2021

Manager of Adv. Engrg. & Technical Lead (Machine Learning in Welding)

At SKC Engineering (part of the global Applus+ group), I had the chance to lead some really exciting work in advanced welding engineering. We acted as a sort of ‘innovation hub,’ helping clients across North America ensure their industrial infrastructure, like transportation systems and energy facilities, was built to last. It was a great place to combine high-level engineering with global service delivery.

My goal when I joined was to take all that deep welding science and turn it into practical, repeatable systems. Instead of looking at every project as a one-off task, I focused on building a ‘knowledge engine’ that could help companies make smart manufacturing decisions quickly and consistently. It was all about bridging the gap between the lab and the actual workspace.

I led the team in creating digital platforms that use a bit of ‘tech magic’, combining traditional physics with machine learning. This helped us move away from slow, manual studies toward automated systems. A great example was the DeepWeld project, where we built tools to help operators predict things like heat distortion and ensure everything was structurally sound before the first spark even flew.

Beyond the tech, I was really focused on the responsibility side of things. I wanted to make sure our tools gave leaders and operators the clear info they needed to make safe, confident decisions. For me, it was about creating a system where safety and reliability were built into the very foundation of how the company operated.

This experience really sparked a ‘lightbulb moment’ for me. I realized that the future isn’t just in the tools, but in embedding that advanced perception directly into the robots and machines themselves. That’s exactly what led me to my current chapter: bringing smart automation and robotics to life in a way that changes how the industry works.

Life Prediction Technologies Inc & University of Ottawa

Industrial PDA with Life Prediction Technologies Incorporation (LPTi) (Ottawa, ON, Canada) May 2011 - January 2015

PDA - R&D Associate

Back during my time at the University of Ottawa, I really dove into the world of industrial materials. I was fascinated by how the ‘bones’ of big structures age over time and how we can use math and computers to predict that. It was all about keeping public infrastructure safe and reliable, making sure the bridges and buildings we rely on every day stay strong for years to come.

While I was there, I had a great opportunity to team up with Life Prediction Technologies. We worked together on creating smarter maintenance schedules for the kinds of equipment you’d see in civilian energy plants. Essentially, we took complex data and turned it into a practical ‘to-do list’ to make sure power plants and energy facilities stay in top shape and run without a hitch

That experience really shaped how I think as a leader today. It taught me that high-level engineering isn’t just about the models; it’s about being a responsible steward of the technology. I learned that my job is to take all those technical details and communicate them clearly so that we can make safe, smart choices for the community. It’s the foundation for everything I do now, making sure our tech supports accountable, real-world manufacturing.

Goldak Technologies Inc & Carleton University

P/T while doing Ph.D., my supervisor's company (Ottawa, ON, Canada) September 2007 - April 2011

Computational Product Engineer

In my role as a Computational Product Engineer, my main mission was to take high-level science and turn it into user-friendly software for the factory floor. I worked on simulation tools that help engineers understand how heat affects metal during the welding process. Basically, I helped build the ‘virtual lab’ that lets companies ensure their welds are strong and durable before they even start the job.

A big part of what I did was making sure the math actually matched what was happening in the real world. I spent a lot of time looking at actual welding data to make sure our software was accurate and practical. I even worked on ways to let users quickly test out different welding settings on their computer, so they could find the most efficient way to get the job done right.

This job also taught me a lot about the responsibility of building software that people rely on. I wanted to make sure our tools weren’t just giving answers, but were also being transparent about how they got there. It taught me that to earn a customer’s trust, an engineering product has to be robust, clear, and easy to understand. That mindset of ‘quality first’ has stayed with me through every leadership role I’ve had since.